Stepper Motor Basics

A stepper motor is an electromechanical device which converts electrical pulses into discrete mechanical movements. The shaft or spindle of a stepper motor rotates in discrete step increments when electrical command pulses are applied to it in the

proper sequence. The motors rotation has several direct relationships to these applied

input pulses. The sequence of the applied pulses is directly related to the direction of

motor shafts rotation. The speed of the motor shafts rotation is directly related to

the frequency of the input pulses and the length of rotation is directly related to the

number of input pulses applied.

Stepper Motor Advantages and Disadvantages

Advantages

1. The rotation angle of the motor is proportional to the input pulse.

2. The motor has full torque at standstill (if the windings are energized)

3. Precise positioning and repeatability of movement since good stepper motors have an accuracy of 3 C 5% of a step and this error is non cumulative from one step to the next.

4. Excellent response to starting/ stopping/reversing.

5. Very reliable since there are no contact brushes in the motor. Therefore the life of the motor is simply dependant on the life of the bearing.

6. The motors response to digital input pulses provides open-loop control, making the motor simpler and less costly to control.

7. It is possible to achieve very low speed synchronous rotation with a load that is directly coupled to the shaft.

8. A wide range of rotational speeds can be realized as the speed is proportional to the frequency of the input pulses.

Disadvantages

1. Resonances can occur if not properly controlled.

2. Not easy to operate at extremely\high speeds.

Open Loop Operation

One of the most significant advantages of a stepper motor is its ability to be accurately controlled in an open loop system. Open loop control means no feedback information about position is needed. This type of control eliminates the need for expensive sensing and feedback devices such as optical encoders. Your position isknown simply by keeping track of the input step pulses.

Stepper Motor Types

There are three basic stepper motor types. They are : Variable-reluctance /Permanent-magnet / Hybrid.

Variable-reluctance

This type of motor consists of a soft iron multi-toothed rotor and a wound stator. When the stator windings are energized with DC current the poles become magnetized.Rotation occurs when the rotor teeth are attracted to the energized stator poles.

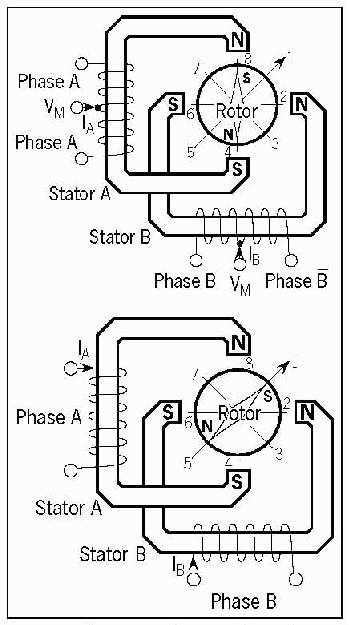

Permanent Magnet (PM)

Often referred to as a tin can orcanstock motor the permanent magnet step motor is a low cost and low resolution type motor with typical step angles of 7.5 to 15. (48 C 24 steps/revolution) PM motors as the name implies have permanent magnets added to the motor structure. The rotor no longer has teeth as with the VR motor. Instead the rotor is magnetized with alternating north and south poles situated in a straight line parallel to the rotor shaft. These magnetized rotor poles provide an increased magnetic flux intensity and because of this the PM motor exhibits improved torque characteristics when compared with the VR type.

Our company is special at the Hybrid Stepper Motor .

The hybrid stepper motor is more expensive than the PM stepper motor but provides better performance with respect to step resolution, torque and speed. Typical step angles for the HB

stepper motor range from 3.6 to 0.9 (100 C 400 steps per revolution). The hybrid stepper motor combines the best features of both the PM and VR type stepper motors. The rotor is multi-toothed like the VR motor and contains an axially magnetized concentric magnet around its shaft. The teeth on the rotor provide an even better path which helps guide the magnetic flux to preferred locations in the airgap. This further increases the detent, holding and dynamic torque characteristics of the motor when compared with both the VR and PM types. The two most commonly used types of stepper motors are the permanent magnet and the hybrid types. If a designer is not sure which type will best fit his applications requirements he should first evaluate the PM type as it is normally several times less expensive.If not then the hybrid motor may be the right choice. There also excist some special stepper motor designs. One is the disc magnet motor. Here the rotor is designed sa a disc with rare earth magnets, See fig. 5 . This motor type has some advantages such as very low inertia and a optimized magnetic flow path with no coupling between the two stator windings. These qualitiesare essential in some applications

Figure 1.Cross-section of hybrid stepper motor

Figure 2.Magenetic flux path through a two-pole stepper motor

With a lag between the rotor and stator.

Figure 3.Unipolar and bipolar wound stepper motor.

Size and Power

In addition to being classified by their step angle stepper motors are also classified according to frame sizes which correspond to the diameter of the body of the motor. For instance a size 11 stepper motor has a body diameter of approximately 1.1 inches. Likewise a size 23 stepper motor has a body diameter of 2.3 inches (58 mm), etc. The body length may however, vary from motor to motor within the same frame size classification. As a general rule the available torque output from a motor of a particular frame size will increase with increased body length. Power levels for IC-driven stepper motors typically range from below a watt for very small motors up to 10 C20 watts for larger motors. The maximum power dissipation level or thermal limits of the motor are seldom clearly stated in the motor manufacturers data. To determine this we must apply the relationship P=V *I. For example, a size 23 step motor may be rated at 6V and 1A per phase. Therefore, with two phases energized the motor has a rated power dissipation of 12 watts. It is normal practice to rate a stepper motor at the power dissipation level where the motor case rises 65C above the ambient in still air. Therefore, if the motor can be mounted to a heatsink it is often possible to increase the allowable power dissipation level. This is important as the motor is designed to be and should be used at its maximum power dissipation ,to be efficient from a size/output power/cost point of view

When to Use a Stepper Motor

A stepper motor can be a good choice whenever controlled movement is required. They can be used to advantage in applications where you need to control rotation angle, speed, position and synchronism. Because of the inherent advantages listed previously, stepper motors have found their place in many different applications. Some of these include printers, plotters, highend office equipment, hard disk drives, medical equipment, fax machines, automotive and many more.

Mechanical Parameters,Load, Friction, Inertia

The performance of a stepper motor system (driver and motor) is also highly dependent on the mechanical parameters of the load. The load is defined as what the motor drives. It is typically frictional, inertial or a combination of the two. Friction is the resistance to motion due to the unevenness of surfaces which rub together. Friction is constant with velocity. A minimum

torque level is required throughout the step in over to overcome this friction ( at least equal to the friction). Increasing a frictional load lowers the top speed, lowers the acceleration and increases the positional error. The converse is true if the frictional load is lowered Inertia is the resistance to changes in speed. A high inertial load requires a high inertial starting torque and the same would apply for braking. Increasing an inertial load will increase speed stability, increase the amount of time it takes to reach a desired speed and decrease the maximum self start pulse rate. The converse is again true if the inertia is decreased. The rotor oscillations of a stepper motor will vary with the amount of friction and inertia load. Because of this relationship unwanted rotor oscillations can be reduced by mechanical damping means however it is more often simpler to reduce these unwanted oscillations by electrical damping methods such as switch from full step drive to half step drive.

Torque vs, Speed Characteristics

The torque vs speed characteristics are the key to selecting the right motor and drive method for a specific application. These characteristics are dependent upon (change with) the motor, excitation mode and type of driver or drive method. A typical speed C torque curve is shown in figure9.

To get a better understanding of this curve it is useful to define the different aspect of this curve.

Figure 4.Torque vs.speed characteristics of a stepper motor.

Holding torque

The maximum torque produced by the motor at standstill.

Pull-In Curve

The pull-in curve defines a area refered to as the start stop region. This is the maximum frequency at which the motor can start/stop instantaneously, with a load applied, without loss of synchronism.

Maximum Start Rate

The maximum starting step frequency with no load applied.

Pull-Out Curve

The pull-out curve defines an area refered to as the slew region. It defines the maximum frequency at which the motor can operate without losing synchronism. Since this region is outside the pull-in area the motor must ramped (accelerated or decelerated) into this region.

Maximum Slew Rate

The maximum operating frequency of the motor with no load applied.

The pull-in characteristics vary also depending on the load. The larger the load inertia the smaller the pull-in area. We can see from the shape of the curve that the step rate affects the torque output capability of stepper motor The decreasing torque output as the speed increases is caused by the fact that at high speeds the inductanceof the motor is the dominant circuit element.

The shape of the speed C torque curve can change quite dramatically depending on the type of driver used. The bipolar chopper type drivers which Ericsson Components produces will maximum the speed C torque performance from a given motor. Most motor manufacturers provide these speed - torque curves for their motors. It is important to understand what driver type or drive method the motormanufacturer used in developing their curves as the torque vs. speed characteristics of an given motor can vary significantly depending on the drive method used.